Three new joint labs will develop new capabilities for high-value sectors such as aerospace and semiconductors

[SINGAPORE] Ultra-precise valves, coatings worth more than the surface they are on, and a material that can resist extremes – these are some of the advanced manufacturing innovations that three Singapore companies are working on with the Agency for Science, Technology and Research (A*Star).

Launched on Oct 3, the joint research projects will yield new technologies in surface treatment, advanced coatings, and precision manufacturing.

These can then be applied to sectors such as aerospace, semiconductors, and life sciences.

These “focused, deep partnerships” help smaller companies “develop differentiated technologies and products that can compete on quality, performance, and sustainability”, said Professor Lim Keng Hui, assistant chief executive of A*Star’s Science and Engineering Research Council.

The projects are worth a total S$21 million in joint investments.

Applied Total Control Treatment: Going skin deep

The combination of A*Star’s research strengths and companies’ industry knowledge is a “match made in heaven”, said Cabal Lo, chief technology officer of participating company Applied Total Control Treatment (ATC).

A NEWSLETTER FOR YOU

Friday, 8.30 am

SGSME

Get updates on Singapore’s SME community, along with profiles, news and tips.

“A*Star is a knowledge stronghold with a lot of talented people who know technology and techniques well. We, on the industry side of things, have clarity of what is needed and how to effectively apply it. That’s how our synergy comes together.”

While multinational companies usually go to suppliers with problems to solve, ATC aims to develop breakthroughs and proactively offer solutions instead, said Lo.

Started in 2004, the surface treatments company has around 150 staff and mainly serves the semiconductor and aerospace sectors.

It specialises in precision, high-performance coatings that reduce friction or increase durability. These can involve tolerances of as little as 4 microns; a human hair, by comparison, is about 200 microns wide.

“In surface treatment, sometimes the science of the coating is more complex, and the value it adds is more than that of the material itself,” said Lo.

ATC and A*Star have produced “a small number” of innovations since they began working together in 2022. With this new project, Lo expects this to reach a total of 10 in the coming years.

The latest partnership will explore how to boost coating performance through greater purity and uniformity, as well as how to make them greener, such as by not using hazardous chemicals.

These increased capabilities will help the company get more clients here and abroad, with the aim being to grow revenue by 20 per cent by 2027.

In an earlier project, ATC and A*Star created a new proprietary process to repair the coating on copper trim panels on an airline’s business class seats, which would otherwise have been replaced entirely.

It was a “triple win”, as Lo puts it: “We were able to save time and cost for the client; upcycle the pieces that no longer have to be thrown away; and extend our capabilities into repairs, rather than just manufacturing.”

Through innovation, Singapore’s manufacturing ecosystem can become more proactive rather than reactive, he said.

“We hope to change the established order and do more than just comply with current expectations, but to be in a position to develop new technology to uplift the ecosystem. Technical collaborations, such as with A*Star, will bear this kind of fruit going forward.”

Abrasive Engineering: Blasting into new markets

Abrasive Engineering (AE) is embarking on its second joint lab with A*Star, following its first in 2020.

Founded in 1990, the SME focuses on surface treatments: changing a material’s surface through processes such as sand-blasting to make it more durable, or in preparation for other steps.

The company, which has 53 employees, also makes surface treatment machines. Its clients are primarily from the aerospace, oil and gas, automotive and medical sectors.

The new project will look into incorporating artificial intelligence and automation into AE’s surface treatment machines, as well as using multiple sensors to enhance the accuracy of high-precision valves used in the treatment process.

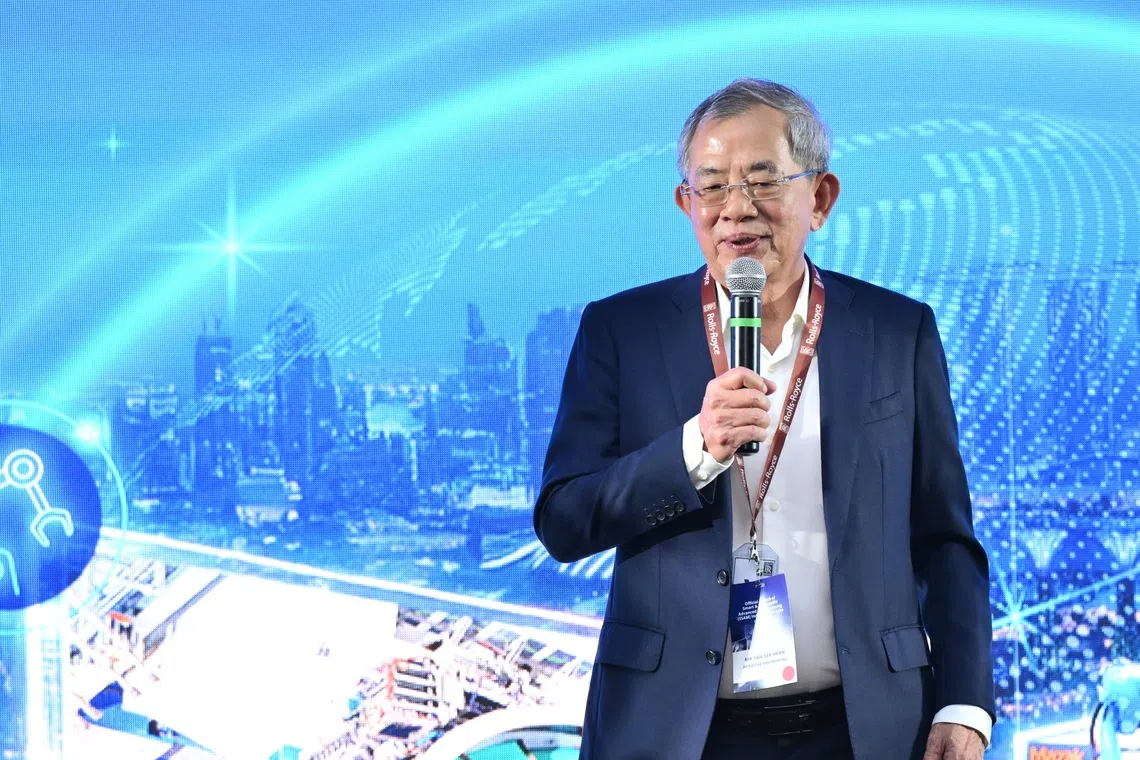

“These (valves) are used in aerospace, oil and gas applications and more, so they need to be very precise,” said executive chairman Tan Ser Hean.

“With this precision valve, we can sell to many more countries and many more customers,” he said, adding that only one other company in the world supplies similar valves.

These new products, along with those created in the first collaboration, are projected to more than double AE’s revenue to S$25 million by 2030, from around S$12 million in 2024.

The first joint lab led to the creation of six products that helped AE expand into new markets overseas and move from being a service provider to selling its own products and technology.

One of the innovations is the world’s first shot-peening media dosing unit that uses microwaves for more precise flow and control. The unit, which controls the flow of the substance used in the shot-peening process, has been was jointly patented by A*Star and AE.

Sales of the new products have helped double the company’s revenue to around S$12 million in 2024, from S$6 million in 2017. With the products, AE could also go beyond its established market of South-east Asia to China, India, South Korea, Japan, Europe, and the US.

Now, AE makes 80 per cent of its revenue from product sales, up from 30 per cent before. The rest comes from services and trading.

“For an SME to be able to sell products globally and to really progress is not simple,” said Tan. “You need to have a very precise, very good product – and the best way to develop that is with A*Star.”

Grand Venture Technologies: Going to extremes

Larger local companies such as Grand Venture Technologies (GVT) have also benefited from joint research.

GVT is a long-established supplier to the semiconductor, medical, life sciences and aerospace industries. As at end-2024, the precision engineering and manufacturing firm had around 1,800 staff in Singapore, Malaysia and China and reported revenue of S$159.5 million.

While listed on the Catalist board of the Singapore Exchange, it will soon be acquired and taken private by Dutch company Aalberts Advanced Mechatronics.

GVT’s three-year project with A*Star is for the manufacturing of advanced ceramic components.

The engineered material is often used in extreme conditions as it is highly resistant to heat, wear and corrosion.

While GVT has used ceramic parts from suppliers before, manufacturing them in-house costs less and creates parts that need less processing.

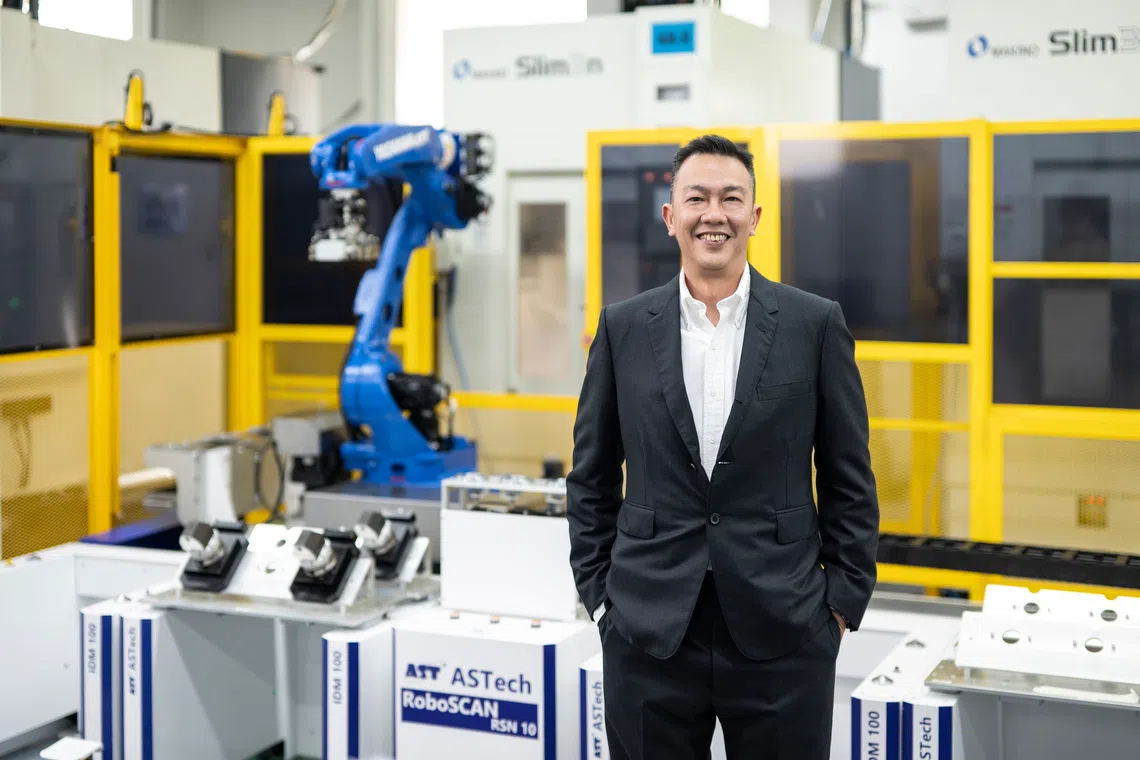

Julian Ng, chief executive officer of Grand Venture Technologies, told BT: “The capability (to make ceramics) can be found in large companies in Europe, the US and Japan. But in South-east Asia, only a handful of companies can do it.”

“We see a gap in the South-east Asia ecosystem for these advanced materials…and it is a good opportunity for us to scale up once we get the know-how.”

Ng sees most of the demand coming from the semiconductor and analytical life sciences industries.

The joint lab will allow the company to meet increasing demand for ceramics from both existing and new clients, and could grow revenue by up to 25 per cent in 2030.

But it is not just GVT that stands to benefit from this research project. New manufacturing methods will generate demands for related processes that can be met by other local suppliers.

“With this joint lab, it benefits the entire Singapore ecosystem as well,” said Ng. “Some of the processes, like raw materials or coatings on the ceramic, can be outsourced to partners in the ecosystem.”